5J1480 135 Thermostat Bimetallic strip low coefficient of expansion

| Ntchito: | Mbale ya Boiler | M'lifupi: | 5mm ~ 120mm |

|---|---|---|---|

| Muyezo: | GB, ASTM, JIS, AISI, BS | Zipangizo: | Bimetal |

| Kukhuthala: | 0.1mm | Dzina la Chinthu: | Mizere ya Bimetallic |

| Mtundu: | Siliva | Mawu Ofunika: | Mzere wa Bimetallic |

| Zofunika Kwambiri: | kuchuluka kochepa kwa kukulaMzere wa bimetallic, 135 Mzere wa Bimetallic, 5J1480Mzere wa bimetallic | ||

Huona Alloy-5J1480(Mzere wa Bimetallic)

(Dzina Lodziwika: 135)

Mzere wa bimetallic umagwiritsidwa ntchito kusintha kusintha kwa kutentha kukhala kusintha kwa makina. Mzerewu uli ndi mizere iwiri ya zitsulo zosiyanasiyana zomwe zimakula pamlingo wosiyana pamene zimatenthedwa, nthawi zambiri chitsulo ndi mkuwa, kapena nthawi zina chitsulo ndi mkuwa. Mizereyi imalumikizidwa pamodzi kutalika kwake konse mwa kuyika riveting, brazing kapena welding. Kukulitsa kosiyanasiyana kumakakamiza mzere wathyathyathya kuti upinde mbali imodzi ngati watenthedwa, ndipo kumbali ina ngati utazizira pansi pa kutentha kwake koyambirira. Chitsulo chokhala ndi coefficient yapamwamba ya kutentha chimakhala kumbali yakunja ya curve pamene mzerewo watenthedwa ndipo kumbali yamkati ikazizira.

Kusuntha kwa mbali kwa mzerewo ndi kwakukulu kwambiri kuposa kukula kwakutali kwa mzerewo mu chimodzi mwa zitsulo ziwirizi. Izi zimagwiritsidwa ntchito m'zida zosiyanasiyana zamakanika ndi zamagetsi. Nthawi zina mzere wa bimetal umagwiritsidwa ntchito ngati wathyathyathya. Nthawi zina, umakulungidwa mu coil kuti ukhale wopapatiza. Kutalika kwakukulu kwa mtundu wopindika kumapereka kukhudzika kwabwino.

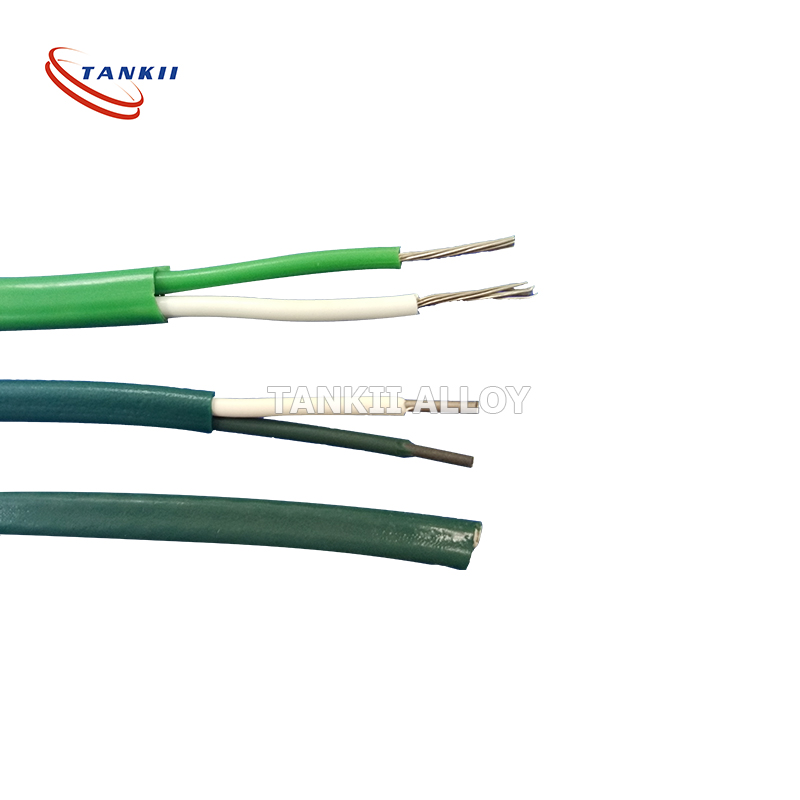

Chithunzi chamzere wa bimetallickusonyeza momwe kusiyana kwa kutentha kwa zitsulo ziwirizi kumatsogolera ku kusuntha kwakukulu kwa mzerewo m'mbali.

Kapangidwe kake

| Giredi | 5J1480 |

| Wowonjezera wokulirapo | Ni22Cr3 |

| Wosanjikiza wochepa | Ni36 |

Kapangidwe ka mankhwala (%)

| Giredi | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Ni36 | ≤0.05 | ≤0.3 | ≤0.6 | ≤0.02 | ≤0.02 | 35~37 | - | - | Mbala. |

| Giredi | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Ni22Cr3 | ≤0.35 | 0.15~0.3 | 0.3 ~ 0.6 | ≤0.02 | ≤0.02 | 21~23 | 2.0~4.0 | - | Mbala. |

Kapangidwe ka thupi

| Kuchulukana (g/cm3) | 8.2 |

| Kukana kwa magetsi pa 20℃ (Ωmm)2/m) | 0.8±5% |

| Kutentha kwa matenthedwe, λ/ W/(m*℃) | 22 |

| Elastic Modulus, E/ Gpa | 147~177 |

| Kupinda K / 10-6℃-1(20~135℃) | 14.3 |

| Kuchuluka kwa kutentha kopindika F/(20~130℃)10-6℃-1 | 26.2%±5% |

| Kutentha kovomerezeka (℃) | -70~ 350 |

| Kutentha kwa mzere (℃) | -20~ 180 |

Kugwiritsa Ntchito: Zipangizozi zimapezeka makamaka muzipangizo zowongolera zokha komanso zida zogwiritsira ntchito (monga: ma thermometers otulutsa utsi, ma thermostats, owongolera ma voltage, kutumizirana kutentha, kusinthana koteteza zokha, mita ya diaphragm, ndi zina zotero) zowongolera kutentha, kubwezera kutentha, malire amagetsi, chizindikiro cha kutentha ndi zinthu zina zomwe zimakhudzidwa ndi kutentha.

Mbali: Makhalidwe oyambira a Thermostat Bimetallic ndi kupindika kwa kupindika ndi kusintha kwa kutentha, zomwe zimapangitsa kuti pakhale nthawi inayake.

Thermostat Bimetallic Strip expansion coefficient ndi yosiyana ndi zigawo ziwiri kapena zingapo za chitsulo kapena alloy zomwe zili pamwamba ponse polumikizana bwino, chifukwa cha kusintha kwa mawonekedwe komwe kumadalira kutentha kumachitika zinthu zogwira ntchito zomwe zimakhudzidwa ndi kutentha. Pomwe coefficient yapamwamba yokulirapo ya active layer ndi active layer yotchedwa low coefficient of expansion ya layer imatchedwa passive layer.

Magulu a zinthu

-

Foni

-

Imelo

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamwamba