Waya Wopondereza Wopanda Manganin Wokhala ndi Manganin Wokhala ndi Manganin Wopanda Manga Wokhala ndi Manga Waya Wopanda Manga

Nicr Yochokera ku Mkuwa WozunguliraAloyi 180Waya Wopopera Wotetezedwa ndi Enameled

1. Kufotokozera Kwathunthu kwa Zinthu

1)

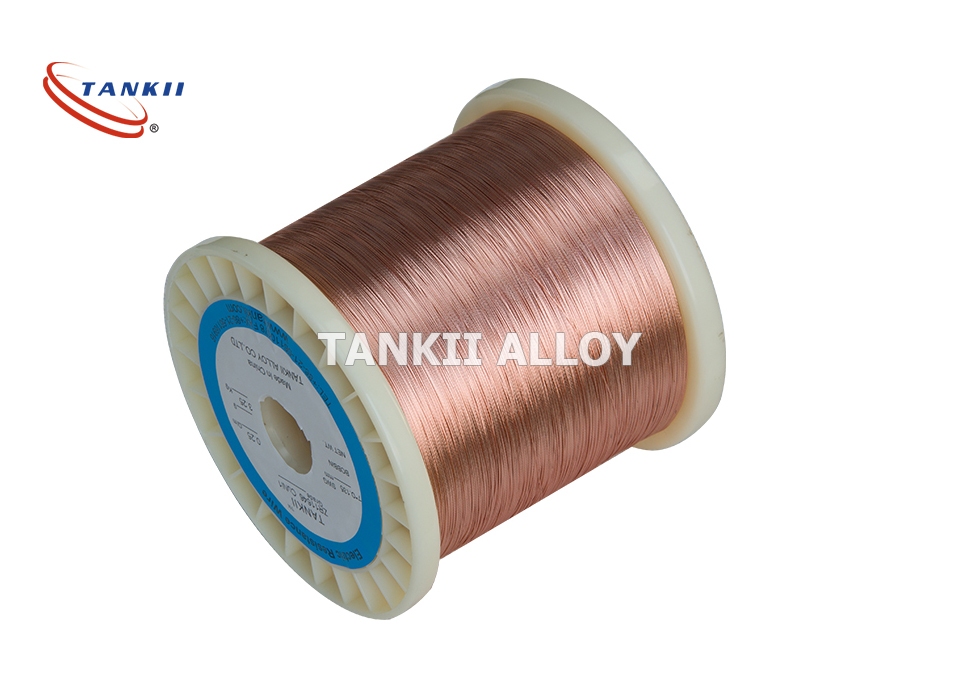

Manganinndi aloyi ya 84% yamkuwa, 12% ya manganese, ndi 4% ya nickel.

Waya wa Manganin ndi foil zimagwiritsidwa ntchito popanga ma resistors, makamaka ammeter shunt, chifukwa cha kukana kwake kutentha pafupifupi zero komanso kukhazikika kwa nthawi yayitali. Ma resistors angapo a Manganin anali ngati muyezo wovomerezeka wa ohm ku United States kuyambira 1901 mpaka 1990. Waya wa Manganin umagwiritsidwanso ntchito ngati chowongolera magetsi m'makina a cryogenic, kuchepetsa kusamutsa kutentha pakati pa malo omwe amafunika kulumikizana ndi magetsi.

Manganin imagwiritsidwanso ntchito mu ma gauge pofufuza mafunde amphamvu (monga omwe amapangidwa ndi kuphulika kwa mabomba) chifukwa imakhala ndi mphamvu yochepa koma mphamvu zambiri za hydrostatic pressure.

2)

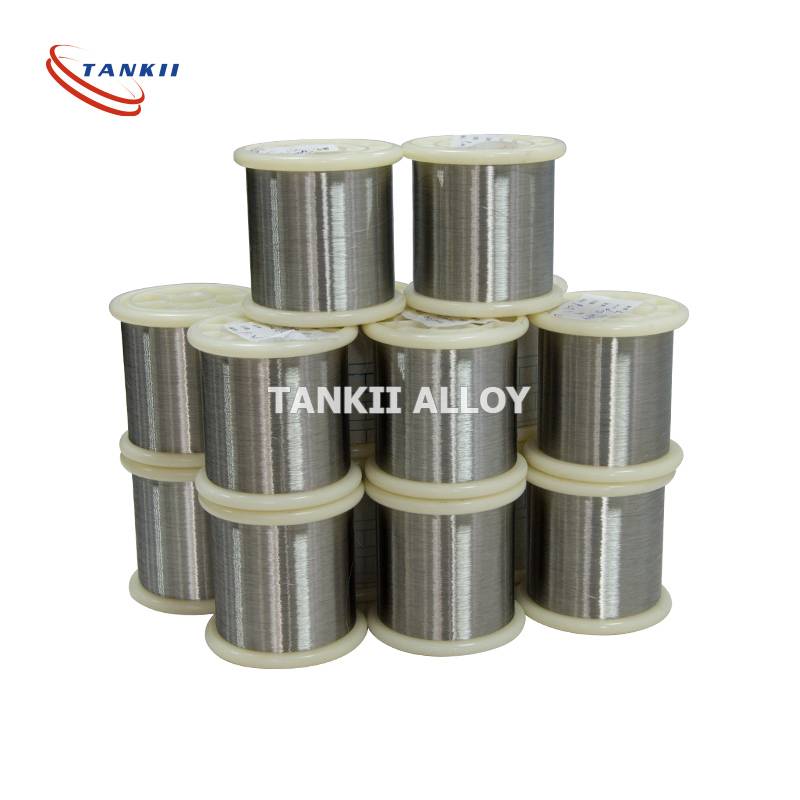

Constantanndi aloyi ya mkuwa ndi nickel yomwe imadziwikanso kutiEureka, PatsogolondiBwatoKawirikawiri imakhala ndi 55% ya mkuwa ndi 45% ya nickel. Chinthu chake chachikulu ndi kukana kwake, komwe kumakhala kosalekeza pa kutentha kosiyanasiyana. Ma alloy ena omwe ali ndi ma coefficients ofanana ndi kutentha kochepa amadziwika, monga manganin (Cu).86Mn12Ni2).

Poyesa mitundu yayikulu kwambiri, 5% (50 000 microstrian) kapena kupitirira apo, annealed constantan (P alloy) ndiye chinthu chomwe chimasankhidwa nthawi zambiri. Constantan mu mawonekedwe awa ndi yopyapyala kwambiri; ndipo, muutali wa gauge wa mainchesi 0.125 (3.2 mm) ndi kupitilira apo, imatha kusefedwa mpaka >20%. Komabe, ziyenera kukumbukiridwa kuti pansi pa mitundu yayikulu ya cyclic alloy, P alloy idzawonetsa kusintha kosatha kwa resistivity ndi kuzungulira kulikonse, ndikuyambitsa kusintha kwa zero kofanana mu strain gauge. Chifukwa cha khalidweli, komanso chizolowezi cha grid kulephera msanga ndi kustrain mobwerezabwereza, P alloy nthawi zambiri salimbikitsidwa kuti igwiritsidwe ntchito pa cyclic strain. P alloy imapezeka ndi manambala a STC a 08 ndi 40 kuti igwiritsidwe ntchito pa zitsulo ndi mapulasitiki, motsatana.

2. Chiyambi cha waya wopangidwa ndi enamel ndi ntchito zake

Ngakhale kuti amatchedwa "enameled", waya wopangidwa ndi enamel kwenikweni sakhala wokutidwa ndi utoto wa enamel kapena ndi enamel ya vitreous yopangidwa ndi ufa wagalasi wosakanikirana. Waya wamakono wa maginito nthawi zambiri umagwiritsa ntchito gawo limodzi kapena anayi (ponena za waya wa quad-film) wa polymer film insulation, nthawi zambiri wamitundu iwiri yosiyana, kuti upereke gawo lolimba komanso losalekeza loteteza. Mafilimu oteteza maginito a maginito amagwiritsa ntchito (motsatira kuchuluka kwa kutentha) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyamide, polyster, polyester-polyimide, polyamide-polyimide (kapena amide-imide), ndi polyimide. Waya wa maginito wotetezedwa ndi polyimide umatha kugwira ntchito mpaka 250 °C. Kuteteza maginito a maginito okhuthala kapena amakona anayi nthawi zambiri kumawonjezeredwa powakulunga ndi polyimide kapena tepi ya fiberglass yotentha kwambiri, ndipo ma windings omalizidwa nthawi zambiri amadzazidwa ndi vacuum ndi varnish yoteteza kuti awonjezere mphamvu yoteteza komanso kudalirika kwa nthawi yayitali kwa ma winding.

Ma coil odzichirikiza okha amakulungidwa ndi waya wokutidwa ndi zigawo ziwiri, lakunja kwambiri ndi thermoplastic yomwe imagwirizanitsa ma turns pamodzi ikatenthedwa.

Mitundu ina ya zinthu zotetezera kutentha monga ulusi wa fiberglass wokhala ndi varnish, pepala la aramid, pepala la kraft, mica, ndi filimu ya polyester imagwiritsidwanso ntchito kwambiri padziko lonse lapansi pazinthu zosiyanasiyana monga ma transformer ndi ma reactor. Mu gawo la mawu, waya wasiliva wopangidwa, ndi zinthu zina zotetezera kutentha, monga thonje (nthawi zina zimadzazidwa ndi chinthu chothira/chokhuthala, monga sera wa njuchi) ndi polytetrafluoroethylene (PTFE) zimapezeka. Zipangizo zakale zotetezera kutentha zimaphatikizapo thonje, pepala, kapena silika, koma izi ndizothandiza pokhapokha ngati kutentha kuli kochepa (mpaka 105°C).

Kuti zikhale zosavuta kupanga, waya wina wa maginito wotentha pang'ono uli ndi chotetezera kutentha chomwe chingachotsedwe ndi kutentha kwa soldering. Izi zikutanthauza kuti kulumikizana kwa magetsi kumapeto kungapangidwe popanda kuchotsa chotetezera kutenthacho kaye.

3. Kapangidwe ka Chemical ndi Katundu Waukulu wa Cu-Ni Low Resistance Alloy

| Gawo la Katundu | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Kapangidwe ka Mankhwala Aakulu | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Mbala | Mbala | Mbala | Mbala | Mbala | Mbala | |

| Kutentha Kwambiri Kosalekeza kwa Utumiki (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Kukhazikika kwa kutentha pa 20oC (Ωmm2/m2) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Kuchulukana (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Kutentha kwa madutsidwe (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Mphamvu Yokoka (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Malo Osungunuka Oyerekeza (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Kapangidwe ka Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Katundu wa Maginito | osati | osati | osati | osati | osati | osati | |

| Gawo la Katundu | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Kapangidwe ka Mankhwala Aakulu | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Mbala | Mbala | Mbala | Mbala | Mbala | Mbala | |

| Kutentha Kwambiri Kosalekeza kwa Utumiki (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Kukhazikika kwa kutentha pa 20oC (Ωmm2/m2) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Kuchulukana (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Kutentha kwa madutsidwe (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Mphamvu Yokoka (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Malo Osungunuka Oyerekeza (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Kapangidwe ka Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Katundu wa Maginito | osati | osati | osati | osati | osati | osati | |

Magulu a zinthu

-

Foni

-

Imelo

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamwamba