Waya wa Enameled Nichrome /Constantan /Copper / Lizt / Waya wa Mtundu / Waya wa Siliva / Twist

Mafotokozedwe Akatundu

Mawaya okana awa a enamel akhala akugwiritsidwa ntchito kwambiri pa zotsutsana wamba, magalimoto

zida zoyezera, zopinga zozungulira, ndi zina zotero. pogwiritsa ntchito njira yotenthetsera yomwe ndi yoyenera kwambiri pa ntchito izi, pogwiritsa ntchito bwino mawonekedwe apadera a enamel coverage.

Kuphatikiza apo, tidzachita kutchinjiriza enamel coating pogwiritsa ntchito waya wachitsulo chamtengo wapatali monga siliva ndi platinamu mukayitanitsa. Chonde gwiritsani ntchito izi popanga payitanitsa.

Mtundu wa Waya wa Nichrome

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

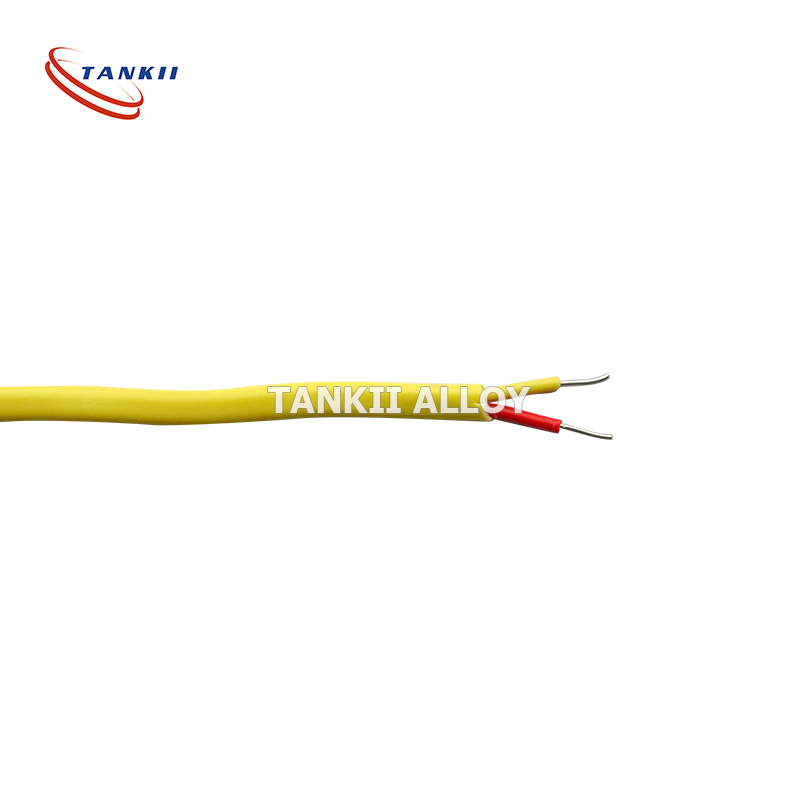

Mtundu wa Kuteteza

| Dzina Lokhala ndi Ma Insulation Enamel | Mlingo wa KutenthaºC (Nthawi yogwira ntchito 2000h) | Dzina la Khodi | Khodi ya GB | Mtundu wa ANSI |

| Waya wopangidwa ndi enamel wa polyurethane | 130 | UEW | QA | MW75C |

| Waya wopangidwa ndi poliyesitala | 155 | PEW | QZ | MW5C |

| Waya wopangidwa ndi enamel wa polyester-imide | 180 | EIW | QZY | MW30C |

| Polyester-imide ndi polyamide-imide yokutidwa kawiriwaya wopangidwa ndi enamel | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Waya wopangidwa ndi enamel wa polyamide-imide | 220 | AIW | QXY | MW81C |

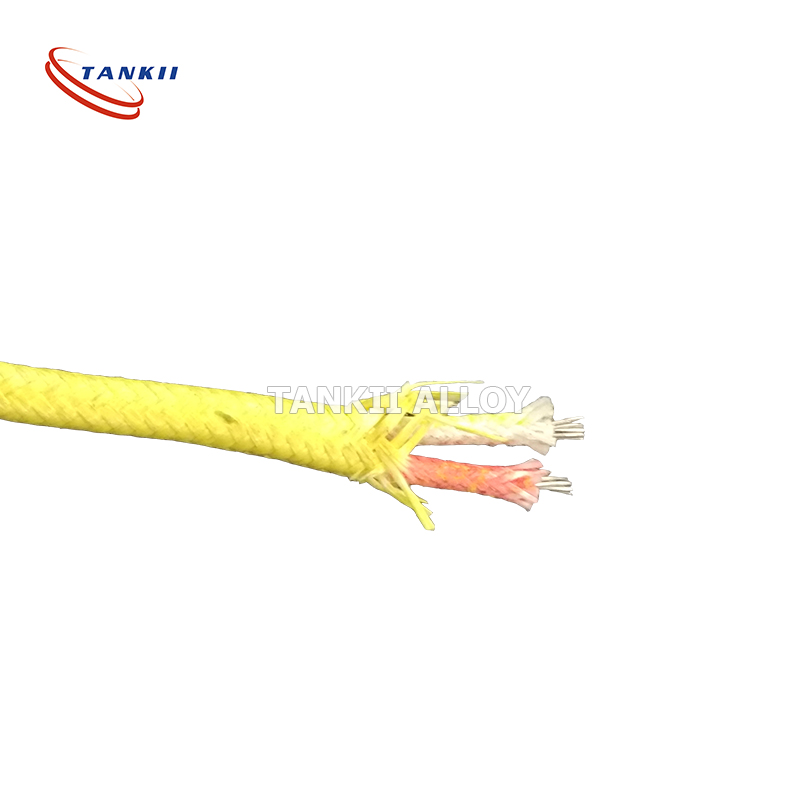

Mtundu wa Waya Wopanda Aloyi

Zingwe zomwe tingapange ndi waya wa Copper-nickel alloy, waya wa Constantan, waya wa Manganin. Waya wa Kama, waya wa NiCr Alloy, waya wa FeCrAl Alloy etc.

| chachikulu katundu mtundu | Cuni1 | CuNI2 | CuNI6 | CuNi8 | CuNI10 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | |

| chachikulu mankhwala kapangidwe kake | Ni | 1 | 2 | 6 | 8 | 10 | 19 | 23 | 30 | 34 | 44 |

| MN | / | / | / | / | / | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| CU | kupuma | kupuma | kupuma | kupuma | kupuma | kupuma | kupuma | kupuma | kupuma | kupuma | |

| kuchuluka kugwira ntchito kutentha | / | 200 | 220 | 250 | 250 | 300 | 300 | 350 | 350 | 400 | |

| kuchulukana g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| kukana pa 20 °c | 0.03 ± 10% | 0.05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | |

| kutentha koyeloji ya kukana | <100 | <120 | <60 | <57 | <50 | <25 | <16 | <10 | -0 | <-6 | |

| kukoka mphamvu mpa | >210 | >220 | >250 | >270 | >290 | >340 | >350 | >400 | >400 | >420 | |

| kutalika | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | |

| kusungunuka mfundo °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| koyeloji ya kuyendetsa bwino mphamvu | 145 | 130 | 92 | 75 | 59 | 38 | 33 | 27 | 25 | 23 |

waya wotenthetsera wa nicr8020 alloy

1. Za waya wa Nichrome

Aloyi ya Nichrome imaphatikizapo nickel yoyera, aloyi ya NiCr, aloyi ya Fe-Cr-Al ndi aloyi ya nickel yamkuwa.

Ma alloy a nickel chrome: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, nickel yoyera Ni200 ndi Ni201

2. Ubwino Waukulu ndi Kugwiritsa Ntchito

1. Nikel-chromium, nikel-chromium alloy yokhala ndi kukana kwakukulu komanso kokhazikika, kukana dzimbiri, kukana kwa okosijeni pamwamba ndikwabwino, kukana kutentha kwambiri komanso mphamvu ya zivomerezi, kusinthasintha kwabwino, kugwira ntchito bwino komanso kusinthasintha.

2.Zogulitsa zathu zimagwiritsidwa ntchito kwambiri kumakampani opanga mankhwala, makina opangira zitsulo, makampani opanga magalasi, makampani opanga ceramic, malo opangira zida zapakhomo ndi zina zotero.

1) Kapangidwe ka mankhwala:

| Mtundu | Kapangidwe ka mankhwala | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Osapitirira | |||||||||

| Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | khalani | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | khalani |

| Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | khalani |

| Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | khalani |

2) Kukula ndi Kulekerera

Ngati chinthucho chili pa "M", chiyenera kutsatiridwa ndi muyezo wa GB/T1234-1995.

1) Kukana:

| Mtundu | Cr20Ni80 | Cr20Ni60 | Cr20Ni35 | Cr20Ni30 | ||

| M'mimba mwake mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| kukana (20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |

Magulu a zinthu

-

Foni

-

Imelo

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamwamba