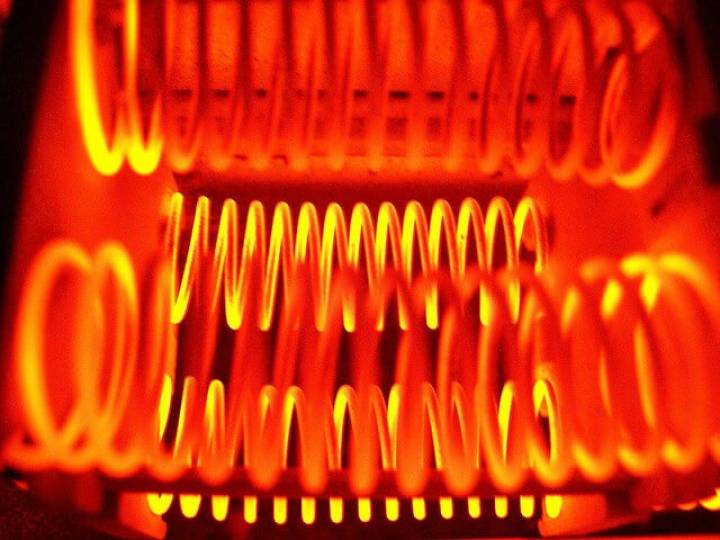

FeCrAl 0Cr25Al5 chotenthetsera chitofu chamagetsi chotenthetsera waya

Katundu Waukulu wa waya wokana kutentha

| Mtundu wa aloyi | M'mimba mwake (mm) | Kusakhazikika (μΩm)(20°C) | Kulimba Mphamvu (N/mm²) | Kutalika (%) | Kupinda Nthawi | Max.Continuous Utumiki Kutentha(°C) | Moyo Wogwira Ntchito (maola) |

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

| DZINA | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Mankhwala Aakulu | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| KUPANGIDWA | Re | mwamwayi | mwamwayi | mwamwayi | mwamwayi | mwamwayi | mwamwayi | mwamwayi |

| Fe | Mpumulo | Mpumulo | Mpumulo | Mpumulo | Mpumulo | Mpumulo | Mpumulo | |

| Nb0.5 | Mwezi 1.8-2.2 | |||||||

| KUTENTHA KWAMBIRI(oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| KULIMBIKITSA 20oC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| KUKWANA (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| KUSINTHA KWA TENTHA | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| CHIWERENGERO(KJ/m·h·oC) | ||||||||

| kuchuluka kwa kukula (α×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| malo osungunuka (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| mphamvu yokoka (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| kutalika (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| kusiyanasiyana kwa dera (%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| kupindika pafupipafupi (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| kuuma (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| kapangidwe ka micrographic | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| katundu wa maginito | Maginito | Maginito | Maginito | Maginito | Maginito | Maginito | Maginito | |

| M'mimba mwake (mm) | Kulekerera (mm) | M'mimba mwake (mm) | Kulekerera (mm) |

| 0.03-0.05 | ±0.005 | >0.50-1.00 | ± 0.02 |

| >0.05-0.10 | ±0.006 | >1.00-3.00 | ±0.03 |

| >0.10-0.20 | ±0.008 | >3.00-6.00 | ± 0.04 |

| >0.20-0.30 | ±0.010 | >6.00-8.00 | ± 0.05 |

| >0.30-0.50 | ± 0.015 | >8.00-12.0 | ± 0.4 |

| Makulidwe (mm) | Kulekerera (mm) | M'lifupi(mm) | Kulekerera (mm) |

| 0.05-0.10 | ±0.010 | 5.00-10.0 | ± 0.2 |

| >0.10-0.20 | ± 0.015 | >10.0-20.0 | ± 0.2 |

| >0.20-0.50 | ±0.020 | >20.0-30.0 | ± 0.2 |

| >0.50-1.00 | ±0.030 | >30.0-50.0 | ± 0.3 |

| >1.00-1.80 | ± 0.040 | >50.0-90.0 | ± 0.3 |

| >1.80-2.50 | ±0.050 | >90.0-120.0 | ± 0.5 |

| >2.50-3.50 | ± 0.060 | >120.0-250.0 | ± 0.6 |

Ife ndife opanga mawaya oletsa kutentha omwe akuphatikizapo

FeCrAL waya, NiCr waya, CuNi waya:

II Ubwino Waukulu ndi Kugwiritsa Ntchito

A. Chizindikiro chakuthupi:

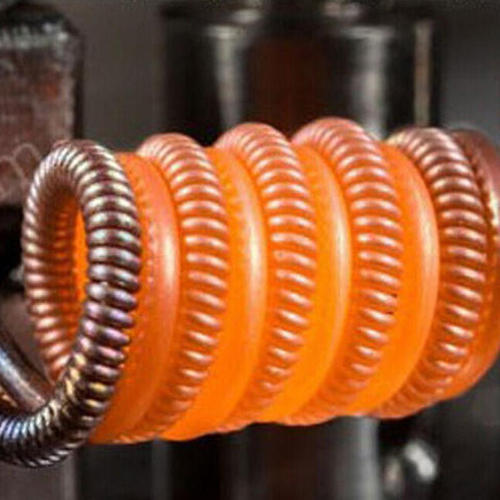

1) Waya m'mimba mwake: 0.025 ~ 15mm

2) Nikeli yeniyeni imatha kupirira kutentha kwambiri popanda kuwonongeka.

kutentha kuli pafupifupi 600°C

3) Waya wa nikeli umapezeka mu chingwe chimodzi kapena zingapo. Umaperekedwa kuchokera kuzinthu zopanda kanthu, kapena zotetezedwa ndi insulation.

B. Makhalidwe:

1) Kuwongoka bwino kwambiri

2) Malo okongola komanso ofanana popanda madontho

3) Luso labwino kwambiri lopanga koyilo

C. Ntchito zazikulu ndi cholinga chachikulu:

1) Waya uwu ungagwiritsidwenso ntchito kwambiri m'magawo odziwika bwino a ma transistor caps, ma anode a machubu apakompyuta,

zingwe zamagetsi / zingwe zolumikizirana ndi zingwe zamagetsi za nyali komanso ma waya. Zimagwiritsidwanso ntchito ngati mzere wa zingwe zosiyanasiyana

ntchito kuphatikizapo mabatire a Ni-Cd

2) Amagwiritsidwanso ntchito pa zingwe, Lead-in-Waya ya nyali, zothandizira machubu apakompyuta, waya wolumikizira mawaya amagetsi

kumene kutentha kuli kopitirira kuposa komwe kumayenera kupangidwa ndi mkuwa, kuluka waya

3) Ntchito zodziwika bwino zimaphatikizapo: zomalizira zotenthetsera monga mu uvuni, mapulasitiki, zotulutsira mpweya, ndi zitofu.

Zothandizira za filament ndi mawaya a lead mumakampani owunikira

Magulu a zinthu

-

Foni

-

Imelo

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamwamba