Takulandilani kumasamba athu!

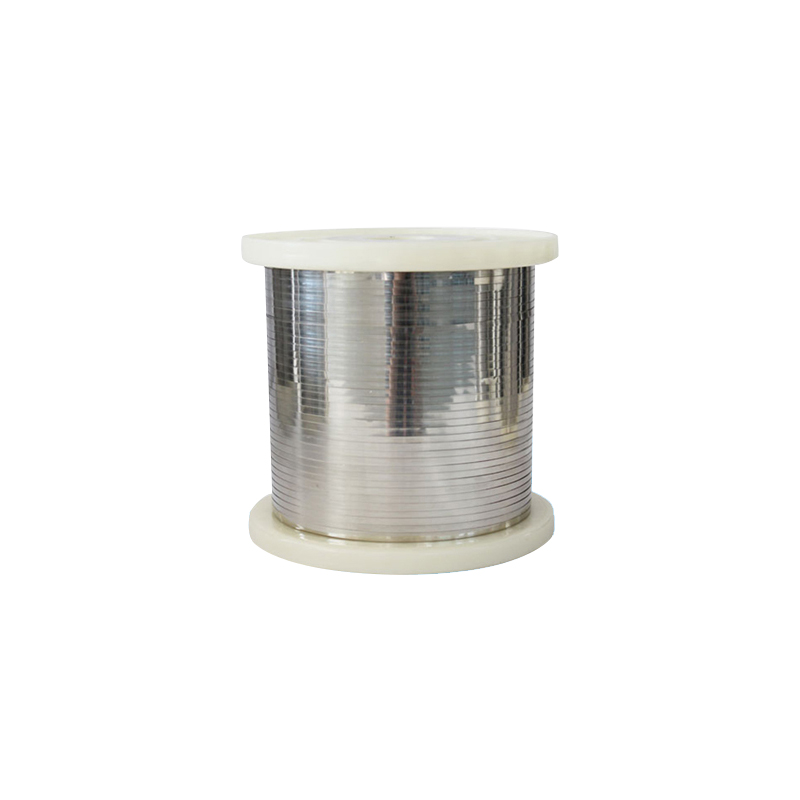

Waya Wapamwamba Wapamwamba wa 0.1mm TK1 FeCrAl Alloy kupita ku Elements Electric Heating Elements

| Kutentha kwambiri (°C) | 1400 |

| Resisivity 20℃(Ω/mm2/m) | 1.48 |

| Kachulukidwe (g/cm³) | 7.1 |

| Thermal Conductivity pa 20 ℃,W/(M·K) | 0.49 |

| Linear Expansion Coefficient(×10¯6/℃)20-1000℃) | 16 |

| Pafupifupi Melting Point(℃) | 1520 |

| Kulimbitsa Mphamvu (N/mm2) | 680-830 |

| Kutalikira (%) | ›10 |

| Kusintha kwa Gawo (%) | 65-75 |

| Maginito Katundu | Maginito |

Lembani uthenga wanu apa ndikutumiza kwa ife

Magulu azinthu

-

Foni

-

Imelo

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Pamwamba