Takulandirani ku mawebusayiti athu!

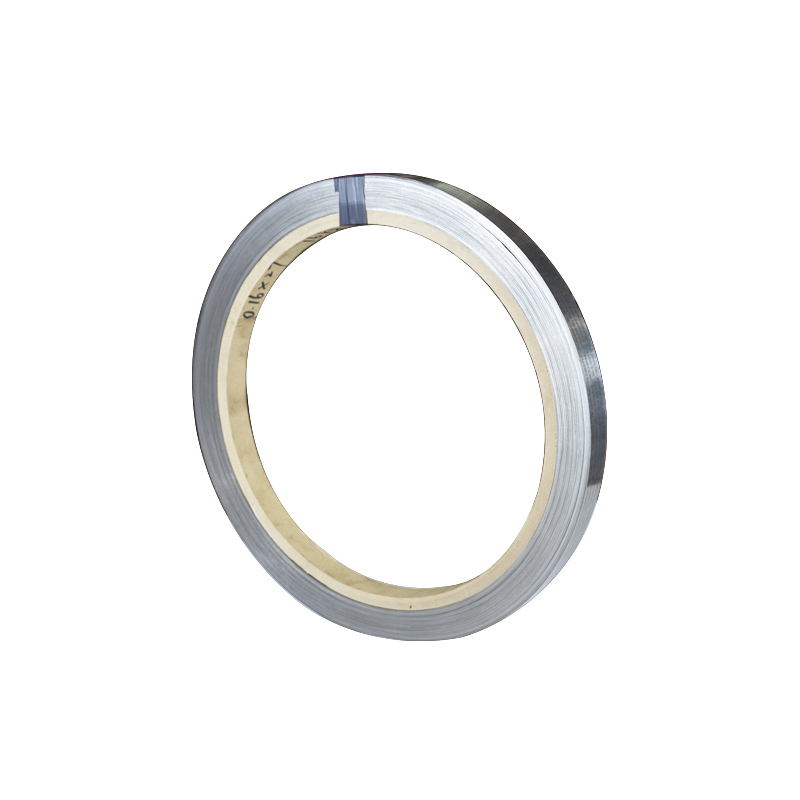

Muli ТБ2013/TM-2/108SP Bimetallic Strip Yabwino Kwambiri Yowongolera Kutentha

Mafotokozedwe Akatundu

Mzere wa Bimetallic wa ТБ2013/TM-2/108SP

Chidule cha Zamalonda

ТБ2013/TM-2/108SP bimetallic strip, yomwe ndi yopangidwa bwino kwambiri komanso yopangidwa ndi Tankii Alloy Material, ndi mtundu wapadera wokonzedwa bwino kuti ugwirizane ndi kutentha kwapakati mpaka kwakukulu. Yopangidwa ndi ma alloy awiri osiyana omwe ali ndi ma coefficients owonjezera kutentha omwe amalamulidwa bwino—olumikizidwa kudzera muukadaulo wa Huona wodziwika bwino wothira kutentha—mzerewu umaphatikiza zabwino zitatu zazikulu: kuyankha kutentha kokhazikika, kukana kutopa kwa makina, komanso kusinthasintha kwachilengedwe. Mosiyana ndi ma bimetallic strips wamba, mtundu wa ТБ2013/TM-2/108SP umapangidwa kuti ugwirizane ndi kutentha komanso mphamvu ya kapangidwe kake, zomwe zimapangitsa kuti ikhale yoyenera ma thermostats amafakitale, zoteteza kutentha kwambiri zamagalimoto, ndi zigawo zolondola zolipirira kutentha m'malo ovuta kugwira ntchito (monga chinyezi chambiri, kugwedezeka).

Ma Standard Designs & Core Composition

- Kalasi ya Zamalonda: ТБ2013/TM-2/108SP

- Kapangidwe kake: Kawirikawiri kamakhala ndi "gawo lokulitsa kwambiri" ndi "gawo lokulitsa pang'ono"; mphamvu yolumikizirana pakati pa nkhope ≥140 MPa

- Miyezo Yogwirizana: Imatsatira GOST 28561-90 (muyezo waku Russia wa mipiringidzo ya bimetallic) ndi IEC 60694 ya zida zowongolera kutentha; imagwirizana ndi zofunikira za EU RoHS

- Wopanga: Tankii Alloy Material, yovomerezeka ndi ISO 9001 ndi ISO 14001, yokhala ndi kapangidwe ka alloy mkati ndi mphamvu zomangira zophatikizana kuti zigwirizane ndi zofunikira za magwiridwe antchito a kalasiyo.

Ubwino Waukulu (motsutsana ndi Ma Bimetallic Strips Omwe Amagwiritsidwa Ntchito Pamodzi ndi Ena)

ТБ2013/TM-2/108SP imadziwika bwino chifukwa cha magwiridwe ake ogwiritsira ntchito, pothana ndi mavuto omwe amakumana nawo m'mafakitale komanso m'malo ovuta kugwiritsa ntchito:

- Kusinthasintha kwa Kutentha Kwambiri: Imagwira ntchito mokhazikika mu -50℃ mpaka 250℃ (kugwiritsa ntchito mosalekeza), ndi kukana kwakanthawi kochepa mpaka 300℃—kuposa mipiringidzo yokhazikika ya bimetallic (yochepera ≤200℃) ndipo ndi yoyenera pazinthu zamafakitale zotentha kwambiri (monga masensa a injini).

- Hysteresis Yotsika Kwambiri: Cholakwika cha Hysteresis ≤3℃ (pakati pa malo otenthetsera ndi kuziziritsa) pa 150℃—chofunika kwambiri pakuwongolera kutentha kolondola (monga ma thermostat a uvuni wa mafakitale) pomwe nthawi yobwerezabwereza yoyatsa/kuzima imafuna malire ofanana.

- Kukana Kutopa Kwambiri: Imapirira kutentha kwa ≥15,000 (-50℃ mpaka 250℃) popanda kusokoneza pakati pa nkhope kapena kuwonongeka kwa magwiridwe antchito—nthawi yogwira ntchito yayitali katatu kuposa mipiringidzo yotsika, zomwe zimachepetsa ndalama zokonzera zida zogwirira ntchito nthawi yayitali (monga machitidwe a HVAC).

- Kukana Kugwedezeka & Kudzimbidwa: Mphamvu yopingasa yopingasa ≥460 MPa imatsimikizira kukhazikika kwa kapangidwe kake pansi pa kugwedezeka (kogwirizana ndi mayeso a kugwedezeka a IEC 60068-2-6); zinc-plating yosankha imapereka kukana kwa kupopera mchere kwa maola 96 (ASTM B117) m'malo okhala ndi chinyezi kapena zowononga (monga zida zam'madzi).

- Kulondola Kofanana kwa Magawo: Kumapezeka m'makulidwe ofanana (0.15mm–0.8mm) ndi m'lifupi (10mm–200mm) ndi kulolerana ≤±0.005mm (kukhuthala) ndi ≤±0.1mm (m'lifupi)—kulola kusindikiza ndi kuphatikiza zinthu zokhazikika zamafakitale.

Mafotokozedwe Aukadaulo

| Khalidwe | Mtengo (Wamba) |

|---|---|

| Makulidwe osiyanasiyana | 0.15mm – 0.8mm (mpaka 1.2mm) |

| M'lifupi mwake | 10mm – 200mm (m'lifupi mwake: 15mm, 20mm, 27mm) |

| Kutalika pa Mpukutu uliwonse | 50m – 300m (kutalika kodulidwa kulipo: ≥100mm) |

| Chiŵerengero cha Kukulitsa Kutentha (Mzere Waukulu/Wotsika) | ~4:1 |

| Kutentha kwa Ntchito | -50℃ mpaka 250℃ (yosalekeza); Kwakanthawi kochepa: mpaka 300℃ (≤ ola limodzi) |

| Kupatuka kwa Kutentha kwa Actuation | ±2℃ (pamalo oyeserera, 80℃–200℃) |

| Mphamvu Yopaka Utoto wa Interfacial | ≥140 MPa |

| Mphamvu Yolimba (Yopingasa) | ≥460 MPa |

| Kutalikitsa (25℃) | ≥14% |

| Kukana (25℃) | 0.20 – 0.35 Ω·mm²/m |

| Kukhwima kwa Pamwamba (Ra) | ≤0.8μm (kumaliza kwa mphero); ≤0.4μm (kumaliza kopukutidwa, ngati mukufuna) |

Zofotokozera Zamalonda

| Chinthu | Kufotokozera |

|---|---|

| Kumaliza Pamwamba | Kumaliza kwa mphero (yopanda oxide) kapena yokutidwa ndi zinc/nickel (yoti iteteze dzimbiri) |

| Kusalala | ≤0.1mm/m2 (chofunika kwambiri pakusintha kwa kutentha kofanana ndi kulondola kwa stamping) |

| Kutha kugwira ntchito | Yogwirizana ndi CNC stamping, laser cutting, ndi kupinda; palibe interfacial cracking panthawi yokonza (osachepera kupinda radius ≥3 × makulidwe) |

| Ubwino Wogwirizana | Kulumikizana kwa 100% pakati pa nkhope (palibe mabowo >0.1mm², kotsimikiziridwa kudzera mu X-ray yowunikira ndi kuyesa kwa ultrasound) |

| Kulongedza | Chotsekedwa ndi vacuum m'matumba a aluminiyamu osanyowa okhala ndi mankhwala ochotsera chinyezi; zopopera zamatabwa (za mipukutu) kapena makatoni oletsa kupindika (a mapepala odulidwa) kuti apewe kusinthika. |

| Kusintha | Kusintha kwa kutentha kwa actuation (60℃–220℃), chophimba pamwamba, mawonekedwe osindikizidwa kale (pa mafayilo a CAD a kasitomala), ndi makulidwe/m'lifupi osakhala ofanana |

Mapulogalamu Odziwika

- Kuwongolera Kutentha kwa Mafakitale: Ma thermostat a ma uvuni a mafakitale, ma boiler, ndi machitidwe a HVAC; zowongolera kutentha kwa makina opangira pulasitiki (ogwira ntchito pa 120℃–200℃).

- Chitetezo Chotentha Kwambiri: Zothira magetsi zamagetsi (monga mapampu a mafakitale, ma compressor) ndi ma transformer amphamvu—zimaletsa kutopa mwa kutseka ma circuit pa kutentha kwa 150℃–250℃.

- Magalimoto ndi Zam'madzi: Zosewerera kutentha ndi zoteteza za zipinda zama injini (magalimoto) ndi zida zam'madzi (zosagwedezeka ndi kugwedezeka ndi dzimbiri la madzi amchere).

- Zipangizo Zolondola: Zinthu zolimbitsa kutentha kwa ma pressure gauges, flow meter, ndi ma MEMS sensors—zimathetsa zolakwika zokulitsa kutentha kuti zisunge kulondola kwa muyeso.

- Zipangizo Zapakhomo ndi Zamalonda: Zoteteza kutentha kwambiri kwa zotenthetsera madzi zamagetsi, zoziziritsira mpweya, ndi mafiriji amalonda (ntchito yokhazikika m'malo omwe muli chinyezi chambiri).

Tankii Alloy Material imagwiritsa ntchito njira zowongolera khalidwe la ТБ2013/TM-2/108SP bimetallic strips: gulu lililonse limayesedwa kumeta pakati pa nkhope, kuyesa kukhazikika kwa kutentha kwa 1000-cycle, kuyang'aniridwa kwa dimensional (laser micrometry), ndi kuwerengera kutentha kwa actuation. Zitsanzo zaulere (100mm × 20mm) ndi malipoti atsatanetsatane a magwiridwe antchito (kuphatikiza ma curve a kutentha motsutsana ndi ma curve a kutentha) zimapezeka mukapempha. Gulu lathu laukadaulo limapereka chithandizo chopangidwa mwapadera—monga kukonza kwa alloy layer kuti kutentha kugwiritsidwe ntchito komanso chitsogozo chogwirizana ndi njira zopangira mafakitale—kuti zitsimikizire kuti strip ikukwaniritsa zosowa zenizeni za mafakitale aku Europe ndi padziko lonse lapansi.

Lembani uthenga wanu apa ndipo mutitumizireni

Magulu a zinthu

-

Foni

-

Imelo

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamwamba