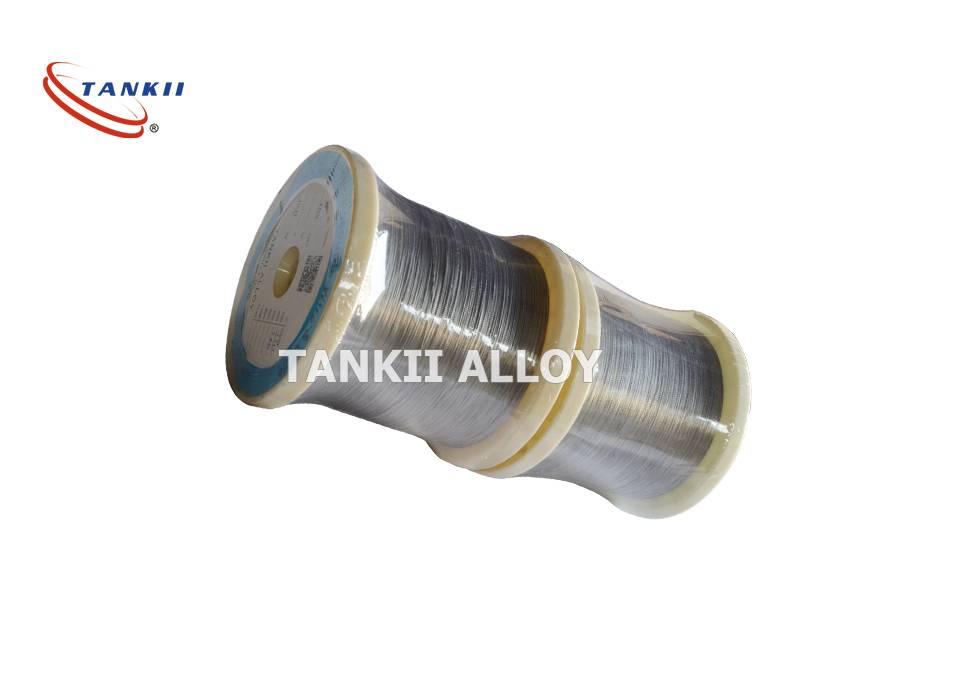

OCr21AI4 (214), FCHW-2, Waya Wotentha wa Mtundu wa Spring wa Waya Wotenthetsera wa Fecral mu Ng'anjo

OCr21AI4 (214), FCHW-2, Waya Wotentha wa Mtundu wa Spring wa Waya Wotenthetsera wa FeCrAl mu Ng'anjo

0Cr21Al4

Zina zambiri

FeCrAl, banja la zitsulo zachitsulo-chromium-aluminium (Kanthal APM, A-1, D ndi AF etc.) zomwe zimagwiritsidwa ntchito m'njira zosiyanasiyana zotetezera komanso kutentha kwambiri zimagwiritsidwanso ntchito ngati mawaya otetezera.

Dzina: waya wotenthetsera

mtundu: okosijeni kapena kuwala

Phukusi: Katoni kapena bokosi lamatabwa monga momwe akufunira

Kugwiritsa ntchito: kupanga zida zotenthetsera monga ng'anjo yamafakitale, zida zotenthetsera zapakhomo, zotsutsana zamagetsi zosiyanasiyana ndi zotsutsana ndi mabuleki a locomotive

Malo Oyambira: Jiangsu, China (Kumtunda)

| Udindo | Zigawo | |||||||

| Ni | Fe | Zn | Mn | Cu | AI | Cr | Si | |

| NCHW-1 | Mphindi 77 | 2.5 Max | 19~21 | 0.75~1.5 | ||||

| NCHW-2 | Mphindi 57 | 1.5 Max | 15~18 | 0.75~1.5 | ||||

| FCHW-1 | rem | 1.0 Max | 4.0~6.0 | 23~26 | Mphindi 1.5 | |||

| FCHW-2 | rem | 1.0 Max | 2.0~4.0 | 17~22 | Mphindi 1.5 | |||

Kagwiritsidwe: Wotsutsa

Kukula: Kukhuthala 0.01-7mm, m'lifupi 1mm-1000mm

Pamwamba: BA, 2B

| Zinthu zopangira aloyi | Mankhwala opangidwa % | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | ena | |

| kuchuluka (≤) | ||||||||||

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.60 | 20.0-23.0 | Mpumulo | ≤0.50 | ≤1.0 | - |

| Cr30Ni70 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.60 | 28.0-31.0 | Mpumulo | ≤0.50 | ≤1.0 | - |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.60 | 15.0-17.0 | 55.0- 61.0 | ≤0.50 | Mpumulo | - |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1 | 1.00-3.00 | 18.0-21.0 | 34.5-36.0 | - | Mpumulo | - |

| Cr20Ni30 | 0.08 | 0.02 | 0.015 | 1 | 1.00-2.00 | 18.0-21.0 | 30.0-31.5 | - | Mpumulo | - |

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | - | 3.5-4.5 | Mpumulo | - |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | - | 4.5-5.3 | Mpumulo | - |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | Mpumulo | - |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | Mpumulo | - |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | Mpumulo | - |

| 1Cr20Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | Mpumulo | - |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | Mpumulo | Nb add0.5 |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | Mpumulo | |

mu mawonekedwe a waya, riboni ndi mzere

Waya: 0.018mm-10mm

Riboni: 0.05*0.2mm-2.0*6.0mm

Chingwe: 0.5 * 5.0mm-5.0 * 250mm

Kulongedza ndi Kutumiza

| Tsatanetsatane wa Phukusi: | filimu ya pulasitiki mkati, mapaleti amatabwa kunja, sankhani kulongedza koyenera, ikhoza kusinthidwa malinga ndi zomwe makasitomala akufuna. |

|---|---|

| Tsatanetsatane wa Kutumiza: | pafupifupi masiku 5-25 |

CHIFUKWA CHIYANI TISANKHE IFE?

Zipangizo zathu zonse zimapangidwa ndi zinthu zofunika kwambiri, osati zinthu zobwezeretsanso. Tili ndi zaka zoposa 10 zogwira ntchito popanga zinthu zotenthetsera zotsutsana ndi kutentha.

Msika, si ma alloy onse a NiCr omwe ali ndi kapangidwe ka mankhwala wamba komanso kukana kokhazikika. Ukatswiri komanso wodalirika ndiye moyo wa bizinesi yathu.

1) Timapeza zinthu zokhazikika kuyambira pakusungunula mpaka zinthu zonse, timatha kupereka zinthu zokhutiritsa.

2) Tili ndi makina apamwamba kwambiri padziko lonse lapansi a ALD - VIDP1000 - 8000KG opangidwa ndi vacuum induction furnace ndi waya ochokera ku Japan.

3) Ndi luso lathu lotha kugwiritsa ntchito bwino zinthu, takulitsa bwino kulemera kwa spool. Mwachitsanzo, ngakhale waya wopyapyala kwambiri wa 0.04 mm m'mimba mwake ukhoza kukulungidwa ndikutumizidwa pa bobbin ya 3 - 4 kg, motero nthawi yomweyo zimathandizira kuti mugwire bwino ntchito.

4) Pofuna kupewa kuti waya usamasuke, tayambitsa makina owongolera mphamvu mu makina athu onyamula ndi obwezeretsanso magetsi.

Magulu a zinthu

-

Foni

-

Imelo

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamwamba