Takulandirani ku mawebusayiti athu!

Kupereka Katswiri kwa Riboni ya ASTM TM2 Bimetallic, Yokhazikika komanso Yodalirika

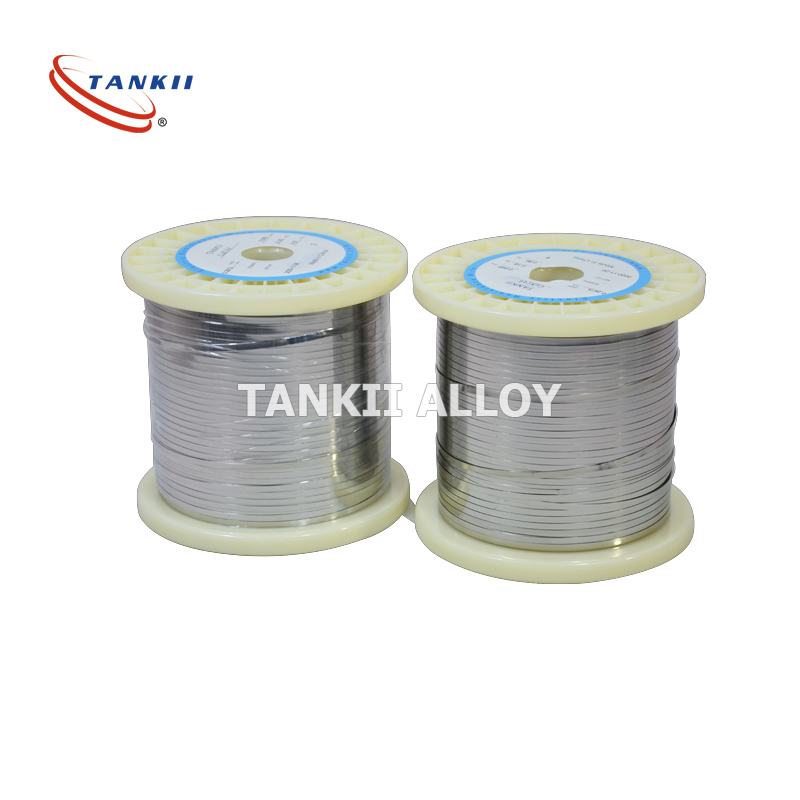

Mafotokozedwe Akatundu

ASTMTM2riboni ya bimetalDzina Lomwe: Truflex P675R, Chace 7500,Telcon200, Kan 200)

Bimetallic ASTM TM2 imakhala ndi mphamvu zambiri zotenthetsera komanso mphamvu zodzitetezera, koma mphamvu yokhazikika komanso kupsinjika kovomerezeka ndi yotsika, imatha kusintha mphamvu ya chipangizocho, kuchepetsa kukula ndikuwonjezera mphamvu.

Bimetallic ASTM TM2 imakhala ndi mphamvu zambiri zotenthetsera komanso mphamvu zodzitetezera, koma mphamvu yokhazikika komanso kupsinjika kovomerezeka ndi yotsika, imatha kusintha mphamvu ya chipangizocho, kuchepetsa kukula ndikuwonjezera mphamvu.

Kapangidwe kake

| Giredi | ASTM TM2 |

| Wowonjezera wokulirapo | Mn75Ni15Cu10 |

| Wosanjikiza wochepa | Ni36 |

Kapangidwe ka mankhwala(%)

| Giredi | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Ni36 | ≤0.05 | ≤0.3 | ≤0.6 | ≤0.02 | ≤0.02 | 35~37 | - | - | Mbala. |

| Giredi | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Mn72Ni10Cu18 | ≤0.05 | ≤0.5 | Mbala. | ≤0.02 | ≤0.02 | 9~11 | - | 17~19 | ≤0.8 |

Kapangidwe ka thupi

| Kuchulukana (g/cm3) | 7.7 |

| Kukana kwa magetsi pa 20ºC(ohm mm2/m) | 1.13 ± 5% |

| Kutentha kwa matenthedwe, λ/ W/(m*ºC) | 6 |

| Elastic Modulus, E/ Gpa | 113~142 |

| Kupinda K / 10-6 ºC-1 (20~135ºC) | 20.8 |

| Kuchuluka kwa kutentha kopindika F/(20~130ºC)10-6ºC-1 | 39.0%±5% |

| Kutentha kovomerezeka (ºC) | -70~ 200 |

| Kutentha kwa mzere (ºC) | -20~ 150 |

Ntchito:Zipangizozi zimagwiritsidwa ntchito makamaka ngati zinthu zotsekera za ceramic zomwe sizikugwirizana ndi maginito mu Gyro ndi zida zina zamagetsi zotsukira mpweya.

Kalembedwe ka zinthu

| Dzina la Aloyi | Mtundu | Kukula | ||

| ASTM TM2 | Mzere | W= 5~120mm | T= 0.1mm | |

Lembani uthenga wanu apa ndipo mutitumizireni

Magulu a zinthu

-

Foni

-

Imelo

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamwamba