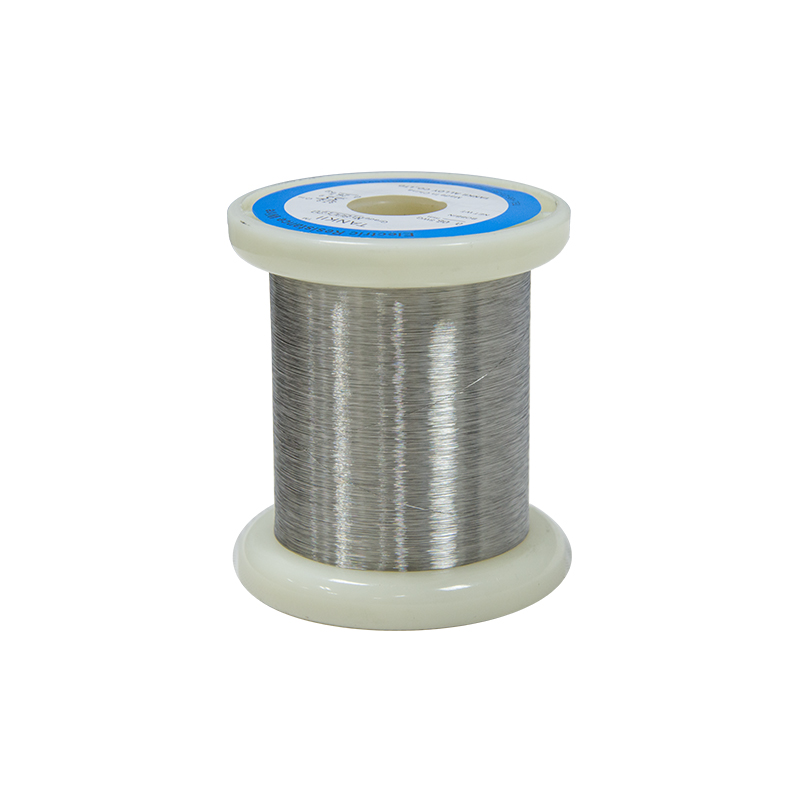

Waya Woyera wa Nikeli Waya wa N6 Nickel 201 Nickel 99.6 wa Nyali

Waya Woyera wa Nikeli Waya wa N6 Nickel 201 Nickel 99.6 wa Nyali

Ni 201

Dzina Lodziwika: N6, N4, Nikeli Yoyera, Nikeli 201

Ma Ni 200 amapangidwa pogwiritsa ntchito njira yapamwamba yosungunula vacuum. Komanso pogwiritsa ntchito forging, rolling, annealing ndi drawing. Amagwiritsidwa ntchito mu zida zamagetsi, lead ya nyale ndi makina a mankhwala. Mzere woyera wa nickel ndi foil, makamaka amagwiritsidwa ntchito m'mabatire, zida zamagetsi, nyale yapadera.

1. Katundu wamakina

| FOMU | Mphamvu Yopereka (Mpa) | Mphamvu Yokoka (Mpa) | Kutalika (%) | Kuuma (RB) | |

| Malo Odyera | Yomalizidwa bwino | 105-310 | 60-85 | 55-35 | 45-80 |

| Wokokedwa ndi ozizira, wotsekedwa | 105-210 | 55-75 | 55-40 | 75-98 | |

| Mzere | Zolimba | 480-795 | 620-895 | 15-2 | >90 |

| Annealed | 105-210 | 380-580 | 55-40 | <70 | |

| Waya | Annealed | 105-345 | 380-580 | 50-30 | |

| Mtima wa Nambala 1 | 275-520 | 485-655 | 40-20 | ||

| Mtima wa Masika | 725-930 | 860-1000 | 15-2 | ||

2. Kapangidwe ka thupi

| Giredi | Kuchulukana (g/cm3) | Kusungunuka kwa Ma Range (ºC) | Malo a Curie (ºC) | Kukana kwa voliyumu (μΩ.cm) | Kutentha kwa mpweya (W/m. ºC) |

| Nickel 201 | 8.89 | 1435-1446 | 360 | 8.5(20ºC) | 79.3(20ºC) |

3. Kapangidwe ka mankhwala (%)

| Giredi | C | Si | Mn | P | S | Ni+Co | Cu | Fe |

| Nickel 201 | <0.02 | <0.35 | <0.35 | <0.01 | >99.0 | <0.25 | <0.40 |

4. Kufotokozera

Mzere: Makulidwe: 0.02mm mpaka 3.0mm, M'lifupi: 1.0mm mpaka 250mm

Waya: M'mimba mwake: 0.025mm mpaka 3.0mm

Pepala/Koyilo: Makulidwe: 0.002-0.125mm

M'lifupi mu coil: 6.00mm max

Mu mbale ndi kutalika kolunjika: 12.00mm max

5. Kagwiritsidwe ntchito

Amagwiritsidwa ntchito mu zida zamagetsi, lead ya nyali ndi makina a mankhwala. Mzere woyera wa nikeli ndi zojambulazo, makamaka zimagwiritsidwa ntchito mu mabatire, zida zamagetsi, ndi nyali yapadera.

6. Mawonekedwe

Kugwira ntchito kokhazikika; Kuletsa kukhuthala; Kukana dzimbiri; Kukhazikika kutentha kwambiri; Kutha kupanga koyilo bwino; Malo ofanana komanso okongola opanda mawanga.

7. Tsatanetsatane wa kulongedza

1) Koyilo (pulasitiki) + bokosi loponderezedwa la ply-wooden + pallet

2) Koyilo (pulasitiki) + katoni + mphasa

8. Zogulitsa ndi ntchito

1). Chiphaso: satifiketi ya ISO9001, ndi chitsimikizo cha SO14001;

2). Ntchito zolipirira pambuyo pogulitsa;

3). Oda yaying'ono yalandiridwa;

4). Makhalidwe okhazikika kutentha kwambiri;

5). Kutumiza mwachangu;

Shanghai Tankii Alloy Material Co., Ltd. Yang'anani kwambiri pakupanga alloy yotsutsa (nichrome Alloy, FeCrAl Alloy, mkuwa)aloyi wa nikeli, waya wa thermocouple, aloyi wolondola komanso aloyi wothira kutentha monga waya, pepala, tepi, mzere, ndodo ndi mbale. Tili kale ndi satifiketi ya ISO9001 komanso kuvomerezedwa kwa dongosolo loteteza chilengedwe la ISO14001. Tili ndi makina onse opangira zinthu zoyeretsera, kuchepetsa kuzizira, kukoka ndi kuchiza kutentha ndi zina zotero. Tilinso ndi mphamvu zodziyimira pawokha za R&D.

Kampani ya Shanghai Tankii Alloy Material Co., Ltd yasonkhanitsa zokumana nazo zambiri kwa zaka 35 pankhaniyi. M'zaka zimenezi, akatswiri otsogola opitilira 60 komanso aluso apamwamba a sayansi ndi ukadaulo adagwiritsidwa ntchito. Adatenga nawo mbali pazochitika zonse za kampani, zomwe zimapangitsa kampani yathu kupitiliza kukula bwino komanso kugonja pamsika wopikisana. Kutengera mfundo ya "ubwino woyamba, ntchito yowona mtima", malingaliro athu oyang'anira akutsata zatsopano zaukadaulo ndikupanga mtundu wapamwamba kwambiri m'munda wa alloy. Tikupitilizabe mu Ubwino - maziko a kupulumuka. Ndi malingaliro athu osatha kukutumikirani ndi mtima wonse ndi moyo wonse. Tadzipereka kupatsa makasitomala padziko lonse lapansi zinthu zapamwamba komanso zopikisana komanso ntchito yangwiro.

Zogulitsa zathu, monga nichrome alloy, precision alloy, thermocouple wire, fecral alloy, copper nickel alloy, thermal spray alloy zatumizidwa kumayiko opitilira 60 padziko lonse lapansi. Tili okonzeka kukhazikitsa mgwirizano wamphamvu komanso wanthawi yayitali ndi makasitomala athu. Mitundu yonse yazinthu zoperekedwa kwa opanga Resistance, Thermocouple ndi Furnace. Ubwino ndi kuwongolera kupanga kuyambira pachiyambi mpaka kumapeto. Thandizo laukadaulo ndi Utumiki kwa Makasitomala.

Magulu a zinthu

-

Foni

-

Imelo

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamwamba