Koyilo ya Masika

pkufotokozera kwa malonda

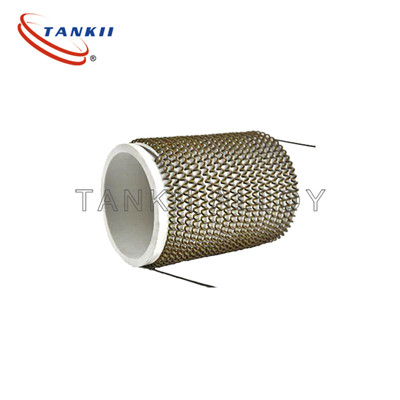

Kampani yathu imapanga mawaya apamwamba kwambiri achitsulo, chromium, aluminiyamu ndi nickel, chromium, omwe amagwiritsa ntchito mphamvu ya waya wa ng'anjo yolamulidwa ndi kompyuta ndipo amapangidwa ndi makina ozungulira othamanga kwambiri. Makhalidwe a chinthuchi ndi awa: kukana kutentha kwambiri, kutentha mwachangu, moyo wautali, kukana kokhazikika, kusinthasintha kwa mphamvu pang'ono, phula lofanana pambuyo potambasula, malo owala komanso oyera; amagwiritsidwa ntchito kwambiri mu uvuni zazing'ono zamagetsi, ng'anjo zoziziritsa kukhosi, zida zotenthetsera ndi zoziziritsira mpweya, ma uvuni osiyanasiyana, machubu otenthetsera magetsi ndi zida zapakhomo, ndi zina zotero. Mipiringidzo yosiyanasiyana ya ng'anjo ya mafakitale ndi ya boma ikhoza kupangidwa ndikupangidwa malinga ndi zosowa za ogwiritsa ntchito.

| Mphamvu W | Vmalo obiriwira V | M'mimba mwake mm | OD mm | Lmphamvu (Chidziwitso) mm | Wmagalamu asanu ndi atatu |

| 300 | 220 | 0.25 | 3.7 | 122 | 1.9 |

| 500 | 220 | 0.35 | 3.9 | 196 | 4.3 |

| 600 | 220 | 0.40 | 4.2 | 228 | 6.1 |

| 800 | 220 | 0.50 | 4.7 | 302 | 11.1 |

| 1000 | 220 | 0.60 | 4.9 | 407 | 18.5 |

| 1200 | 220 | 0.70 | 5.6 | 474 | 28.5 |

| 1500 | 220 | 0.80 | 5.8 | 554 | 39.0 |

| 2000 | 220 | 0.95 | 6.1 | 676 | 57.9 |

| 2500 | 220 | 1.10 | 6.9 | 745 | 83.3 |

| 3000 | 220 | 1.20 | 7.1 | 792 | 98.3 |

Kutentha ndi kapangidwe ka mankhwala a waya wotenthetsera

| Giredi | Max. Conti uous Mtima Wogwira Ntchito. | Cr% | Ni% | Al% | Fe% | Re% | Nb% | Mwezi% |

| Cr20Ni80 | 1200℃ | 20~23 | Mbala. |

|

|

|

|

|

| Cr30Ni70 | 1250℃ | 28~31 | Mbala. |

|

|

|

|

|

| Cr15Ni60 | 1150℃ | 15~18 | 55~61 |

| Mbala. |

|

|

|

| Cr20Ni35 | 1100℃ | 18~21 | 34~37 |

| Mbala. |

|

|

|

| TANKII APM | 1425℃ | 20.5~23.5 |

| 5.8 | Mbala. | / |

|

|

| 0Cr27Al7Mo2 | 1400℃ | 26.5~27.8 |

| 6 mpaka 7 | Mbala. |

|

| 2 |

| 0Cr21Al6Nb | 1350℃ | 21~23 |

| 5~7 | Mbala. |

| 0.5 |

|

| 0Cr25Al5 | 1250℃ | 23~26 |

| 4.5~6.5 | Mbala. |

|

|

|

| 0Cr23Al5Y | 1300℃ | 22.5~24.5 |

| 4.2~5.0 | Mbala. |

|

|

|

| 0Cr19Al3 | 1100℃ | 18~21 |

| 3~4.2 | Mbala. |

|

|

|

Makhalidwe akuluakulu aukadaulo a waya wa aloyi wa FeCrAl:

①Kutentha kwa kugwiritsa ntchito kuli kokwera, kutentha kwa waya wa aluminiyamu wachitsulo-chromium mumlengalenga kumatha kufika 1300℃;

②Utumiki wautali;

③Mtolo wovomerezeka pamwamba ndi waukulu;

⑤ Mphamvu yokoka yeniyeni ndi yaying'ono kuposa nickel-chromium alloy; ④Kukana kwa okosijeni ndi kwabwino, ndipo filimu ya AI2O3 yomwe imapangidwa pambuyo pa okosijeni imakhala ndi kukana kwabwino kwa mankhwala komanso kukana kwakukulu;

⑥Kulimba kwambiri;

⑦Kukana bwino sulfure;

Mtengo wake ndi wotsika kwambiri poyerekeza ndi wa nickel-chromium alloy;

⑨Choyipa chake ndi chakuti kutentha kukakwera, kumakhala kosalala, ndipo mphamvu yake ikakwera imakhala yochepa.

Makhalidwe a waya wamagetsi wa nickel-chromium ndi awa:

① Mphamvu kwambiri pa kutentha kwakukulu;

②Ziziritsani mukatha kugwiritsa ntchito kwa nthawi yayitali, zinthuzo sizidzasweka;

③Kutulutsa kwa aloyi ya Ni-ming yosungunuka kwathunthu ndi kwakukulu kuposa kwa aloyi ya Fe-Cr-Al;

④Palibe mphamvu ya maginito;

⑤Kupatula mlengalenga wa sulfure, uli ndi kukana bwino dzimbiri

Magulu a zinthu

-

Foni

-

Imelo

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamwamba