Waya wa 0.2mm 130 Class Enameled Waya Wozungulira Wokhala ndi Manganin

Waya Wozungulira Wamkuwa wa Manganin Wokhala ndi Enameled wa Class 130

1. Kufotokozera Kwathunthu kwa Zinthu

Chotsukira cha nickel cha mkuwa, chomwe chili ndi mphamvu zochepa zamagetsi, sichimatentha bwino komanso sichimazizira, chosavuta kuchikonza ndikuchilumikiza ndi lead. Chimagwiritsidwa ntchito popanga zinthu zofunika kwambiri mu thermal overload relay, low resistance thermal circuit breaker, ndi zida zamagetsi. Ndi chinthu chofunikira kwambiri pa chingwe chotenthetsera chamagetsi. Chimafanana ndi s type cupronickel. Nickel ikapangidwa kwambiri, pamwamba pake pamakhala siliva woyera kwambiri.

3. Kapangidwe ka Chemical ndi Katundu Waukulu wa Cu-Ni Low Resistance Alloy

| Gawo la Katundu | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Kapangidwe ka Mankhwala Aakulu | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Mbala | Mbala | Mbala | Mbala | Mbala | Mbala | |

| Kutentha Kwambiri Kosalekeza kwa Utumiki (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Kukhazikika kwa kutentha pa 20oC (Ωmm2/m2) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Kuchulukana (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Kutentha kwa madutsidwe (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Mphamvu Yokoka (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Malo Osungunuka Oyerekeza (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Kapangidwe ka Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Katundu wa Maginito | osati | osati | osati | osati | osati | osati | |

| Gawo la Katundu | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Kapangidwe ka Mankhwala Aakulu | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Mbala | Mbala | Mbala | Mbala | Mbala | Mbala | |

| Kutentha Kwambiri Kosalekeza kwa Utumiki (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Kukhazikika kwa kutentha pa 20oC (Ωmm2/m2) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Kuchulukana (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Kutentha kwa madutsidwe (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Mphamvu Yokoka (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Malo Osungunuka Oyerekeza (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Kapangidwe ka Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Katundu wa Maginito | osati | osati | osati | osati | osati | osati | |

2. Chiyambi cha waya wopangidwa ndi enamel ndi ntchito zake

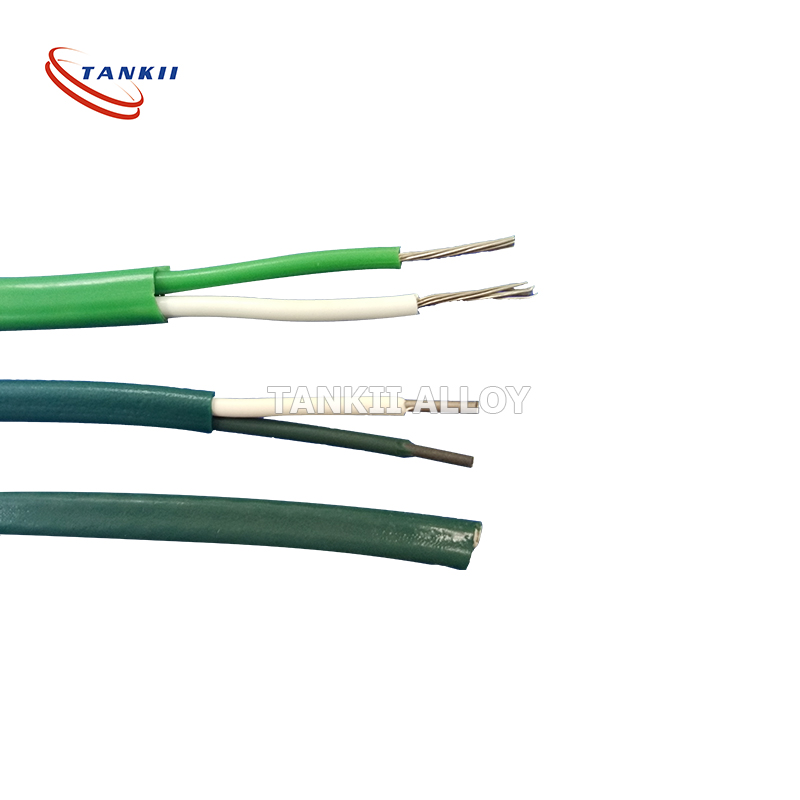

Ngakhale kuti amafotokozedwa kuti ndi "opindika", waya wopindika sakhala wokutidwa ndi utoto wa enamel kapena enamel wa vitreous wopangidwa ndi ufa wagalasi wosakanikirana. Waya wamakono wa maginito nthawi zambiri umagwiritsa ntchito gawo limodzi kapena anayi (ngati waya wamtundu wa quad-film) wa polymer film insulation, nthawi zambiri wamitundu iwiri yosiyana, kuti apereke gawo lolimba komanso losalekeza loteteza. Mafilimu oteteza maginito a maginito amagwiritsa ntchito (motsatira kuchuluka kwa kutentha) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyster,poliyesitala-polyimide, polyamide-polyimide (kapena amide-imide), ndi polyimide. Waya wa maginito wotetezedwa ndi polyimide umatha kugwira ntchito mpaka 250 °C. Kuteteza kwa waya wokhuthala wa sikweya kapena wamakona nthawi zambiri kumawonjezeredwa poukulunga ndi tepi ya polyimide kapena fiberglass yotentha kwambiri, ndipo ma windings omalizidwa nthawi zambiri amathiridwa vacuum ndi varnish yoteteza kuti iwonjezere mphamvu ya kutetezera komanso kudalirika kwa nthawi yayitali kwa ma windings.

Ma coil odzichirikiza okha amakulungidwa ndi waya wokutidwa ndi zigawo ziwiri, lakunja kwambiri ndi thermoplastic yomwe imagwirizanitsa ma turns pamodzi ikatenthedwa.

Mitundu ina yotetezera kutentha monga ulusi wa fiberglass wokhala ndi varnish, pepala la aramid, pepala la kraft, mica, ndipoliyesitalaFilimu imagwiritsidwanso ntchito kwambiri padziko lonse lapansi pa ntchito zosiyanasiyana monga ma transformer ndi ma reactor. Mu gawo la mawu, waya wa siliva, ndi zinthu zina zotetezera kutentha, monga thonje (nthawi zina zimalowetsedwa ndi chinthu chothira/chokhuthala, monga sera wa njuchi) ndi polytetrafluoroethylene (PTFE) zimapezeka. Zipangizo zakale zotetezera kutentha zimaphatikizapo thonje, pepala, kapena silika, koma izi ndizothandiza pokhapokha ngati kutentha kochepa (mpaka 105°C).

Kuti zikhale zosavuta kupanga, waya wina wa maginito wotentha pang'ono uli ndi chotetezera kutentha chomwe chingachotsedwe ndi kutentha kwa soldering. Izi zikutanthauza kuti kulumikizana kwa magetsi kumapeto kungapangidwe popanda kuchotsa chotetezera kutenthacho kaye.

Magulu a zinthu

-

Foni

-

Imelo

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamwamba