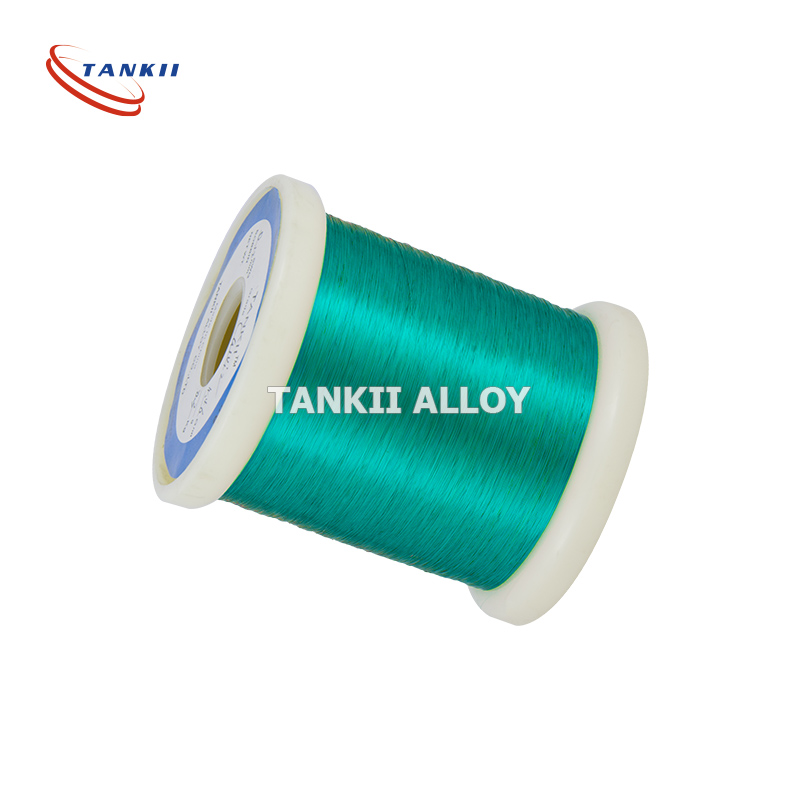

0.2mm 130 Kalasi Enameled Waya Wamitundu Yozungulira Yozungulira Copper Aloyi Manganin

130 Kalasi Yamitundu Yozungulira Copper Alloy Manganin Enameled Waya

1. Kufotokozera Kwazinthu Zonse

Copper nickel alloy, yomwe imakhala ndi mphamvu yochepa yamagetsi, yabwino yosamva kutentha komanso yosamva dzimbiri, yosavuta kukonzedwa komanso kuwotcherera.Amagwiritsidwa ntchito popanga zida zazikulu muzowonjezera zotenthetsera matenthedwe, kutsika kwapang'onopang'ono kwamagetsi, ndi zida zamagetsi.Ndichinthu chofunikiranso pazingwe zamagetsi zamagetsi.Ndizofanana ndi mtundu wa cupronickel. Kuchuluka kwa Nickel kumapangitsa kuti pamwamba pakhale siliva.

3.Chemical Composition ndi Main Property ya Cu-Ni Low Resistance Alloy

| PropertiesGrade | KuNi1 | KuNi2 | KuNi6 | KuNi8 | kuMn3 | KuNi10 | |

| Main Chemical Composition | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bali | Bali | Bali | Bali | Bali | Bali | |

| Kutentha Kwambiri Kwambiri kwa Service(oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Resisivity pa 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Kachulukidwe (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Thermal Conductivity (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Tensile Strength (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Pafupifupi Melting Point (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Kapangidwe ka Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Maginito Katundu | ayi | ayi | ayi | ayi | ayi | ayi | |

| PropertiesGrade | KuNi14 | KuNi19 | KuNi23 | KuNi30 | KuNi34 | KuNi44 | |

| Main Chemical Composition | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bali | Bali | Bali | Bali | Bali | Bali | |

| Kutentha Kwambiri Kwambiri kwa Service(oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Resisivity pa 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Kachulukidwe (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Thermal Conductivity (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Tensile Strength (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Pafupifupi Melting Point (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Kapangidwe ka Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Maginito Katundu | ayi | ayi | ayi | ayi | ayi | ayi | |

2. Enamelled Waya Chiyambi ndi ntchito

Ngakhale amafotokozedwa kuti "enameled", waya wa enameled sikuti amakutidwa ndi utoto wa enamel kapena vitreous enamel yopangidwa ndi ufa wagalasi wosakanikirana.Waya wamakono wa maginito nthawi zambiri umagwiritsa ntchito gawo limodzi kapena zinayi (ngati waya wamtundu wa quad-film) wa insulation ya filimu ya polima, yomwe nthawi zambiri imakhala yamitundu iwiri yosiyana, kuti ikhale yolimba, yosalekeza.Makanema oteteza maginito amawaya amagwiritsa ntchito (kuti awonjezere kutentha) polyvinyl yovomerezeka (Formar), polyurethane, polyimide, polyamide, polyster,poliyesitala-polyimide, polyamide-polyimide (kapena amide-imide), ndi polyimide.Waya wa maginito wa polyimide amatha kugwira ntchito mpaka 250 ° C.Kutsekemera kwa waya wokulirapo kapena maginito amakona anayi nthawi zambiri kumakulitsidwa ndi kukulunga ndi tepi yotentha kwambiri ya polyimide kapena fiberglass, ndipo ma windings omalizidwa nthawi zambiri amalowetsedwa ndi varnish yotchinga kuti apititse patsogolo mphamvu zotchingira komanso kudalirika kwanthawi yayitali.

Mapiritsi odzithandizira okha amavulazidwa ndi waya wokutidwa ndi zigawo ziwiri zosachepera, chakunja chake ndi thermoplastic chomwe chimagwirizanitsa mozungulira chikatenthedwa.

Mitundu ina yotchinjiriza monga ulusi wa fiberglass wokhala ndi vanishi, pepala la aramid, pepala la kraft, mica, ndi filimu ya poliyesitala imagwiritsidwanso ntchito padziko lonse lapansi pazinthu zosiyanasiyana monga zosinthira ndi ma reactor.M'gawo la audio, waya wa zomangamanga zasiliva, ndi zotetezera zina zosiyanasiyana, monga thonje (nthawi zina zodzaza ndi mtundu wina wa coagulating agent / thickener, monga phula) ndi polytetrafluoroethylene (PTFE) angapezeke.Zida zakale zotchinjiriza zinali ndi thonje, mapepala, kapena silika, koma izi ndizothandiza pakugwiritsa ntchito kutentha kochepa (mpaka 105 ° C).

Kuti apange mosavuta, mawaya ena otsika kwambiri a maginito amakhala ndi zotsekera zomwe zimatha kuchotsedwa ndi kutentha kwa soldering.Izi zikutanthauza kuti kulumikizana kwamagetsi kumapeto kumatha kupangidwa popanda kuvula kaye kutchinjiriza.