Kupambana kwakukulu kwamakampani opanga ndege sikungasiyanitsidwe ndi chitukuko ndi kupita patsogolo kwaukadaulo wazinthu zakuthambo.Kutalika kwapamwamba, kuthamanga kwambiri komanso kuyendetsa bwino kwa ndege zankhondo zimafuna kuti zipangizo zamapangidwe a ndegeyo zitsimikizire mphamvu zokwanira komanso zofunikira zouma.Zida zamainjini zimafunikira kukana kutentha kwambiri, ma aloyi otentha kwambiri, zida zophatikizika za ceramic ndizofunikira kwambiri.

Chitsulo wamba chimafewetsa pamwamba pa 300 ℃, kupangitsa kuti ikhale yosayenera kumadera otentha kwambiri.Pofunafuna kutembenuka kwamphamvu kwamphamvu, kutentha kwapamwamba komanso kopitilira muyeso kumafunika m'munda wa mphamvu ya injini ya kutentha.Ma alloys otentha kwambiri apangidwa kuti azigwira ntchito mokhazikika pa kutentha pamwamba pa 600 ℃, ndipo ukadaulo ukupitilizabe kusintha.

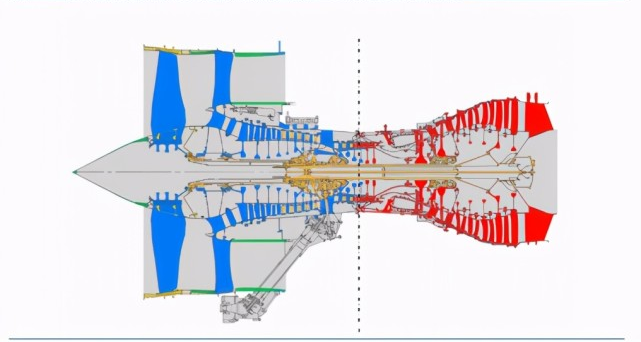

Ma alloys otentha kwambiri ndi zida zofunika kwambiri zama injini zamlengalenga, zomwe zimagawika muzitsulo zokhala ndi chitsulo chotentha kwambiri, nickel-based ndi zinthu zazikulu za alloy.Ma alloys otentha kwambiri akhala akugwiritsidwa ntchito mu injini za aero-injini kuyambira pomwe adayamba, ndipo ndi zida zofunika popanga injini zamlengalenga.Kugwira ntchito kwa injini kumadalira makamaka pa mlingo wa ntchito za zipangizo za alloy kutentha.M'mainjini amakono a aero-injini, kuchuluka kwa aloyi wotentha kwambiri kumakhala 40-60 peresenti ya kulemera konse kwa injini, ndipo amagwiritsidwa ntchito makamaka pazinthu zinayi zazikulu zotentha: zipinda zoyaka moto, maupangiri, masamba a turbine ndi ma turbine discs, ndipo kuwonjezera apo, amagwiritsidwa ntchito pazinthu monga magazini, mphete, zipinda zoyatsira moto ndi ma nozzles amchira.

(Gawo lofiira lachithunzichi likuwonetsa ma aloyi otentha kwambiri)

Ma aloyi a Nickel opangidwa ndi kutentha kwambiri zambiri ntchito pa 600 ℃ pamwamba pa zikhalidwe za kupsinjika maganizo, sikuti ali ndi makutidwe ndi okosijeni wabwino ndi dzimbiri kukana dzimbiri, ndipo ali mkulu-kutentha mphamvu, kukwawa mphamvu ndi kupirira mphamvu, komanso wabwino kutopa kukana.Amagwiritsidwa ntchito kwambiri pazamlengalenga ndi ndege pansi pa kutentha kwambiri, zigawo zamapangidwe, monga masamba a injini ya ndege, ma turbine discs, zipinda zoyaka moto ndi zina zotero.Ma aloyi a nickel-based high-temperature alloys amatha kugawidwa m'magulu opunduka a kutentha kwapamwamba, ma alloys otentha kwambiri komanso ma alloys atsopano otentha kwambiri malinga ndi momwe amapangira.

Ndi kutentha zosagwira aloyi ntchito kutentha ndi apamwamba ndi apamwamba, kulimbikitsa zinthu mu aloyi ndi mochulukira, ndi zovuta zikuchokera, chifukwa ena aloyi angagwiritsidwe ntchito mu boma kutayidwa, sangathe kupunduka processing otentha.Kuphatikiza apo, kuwonjezereka kwa ma alloying kumapangitsa kuti ma alloys opangidwa ndi nickel azilimba ndikulekanitsa kwambiri zigawo, zomwe zimapangitsa kuti pasakhale kufanana kwa bungwe ndi katundu.Kugwiritsa ntchito ufa zitsulo ndondomeko kubala mkulu kutentha aloyi, angathe kuthetsa mavuto pamwamba.Chifukwa cha particles yaing'ono ufa, ufa kuzirala liwiro, kuthetsa tsankho, bwino otentha workability, choyambirira kuponyera aloyi mu otentha workable mapindikidwe a kaloti mkulu-kutentha, mphamvu zokolola ndi kutopa katundu ndi bwino, ufa mkulu-kutentha aloyi kupanga apamwamba -mphamvu zosakaniza zapanga njira yatsopano.

Nthawi yotumiza: Jan-19-2024